Difference between Low Pressure Injection Molding And High Pressure Injection Molding

Low pressure injection molding process has been widely used in industries because of its various advantages in these years. And it has replaced the traditional high pressure injection molding process. What is the difference between high- and low-pressure injection molding process? High pressure vs low pressure, how to choose? We would like to introduce the difference between low-pressure injection molding and high-pressure injection molding process and the advantages of low-pressure injection molding.

What is Low Pressure Injection Molding

Low pressure injection molding is a new injection molding technique that uses low pressure. With this technique, you can inject the hot melted material with the low pressure into the mold cavities, and then solidify the melted material fast within a few seconds to a few minutes. This type of injection molding technology can help improve the speed of production, allowing rapid prototyping services to produce prototypes, parts, and components much faster than usual. It is some kind of production method that different from the 3d printing services.

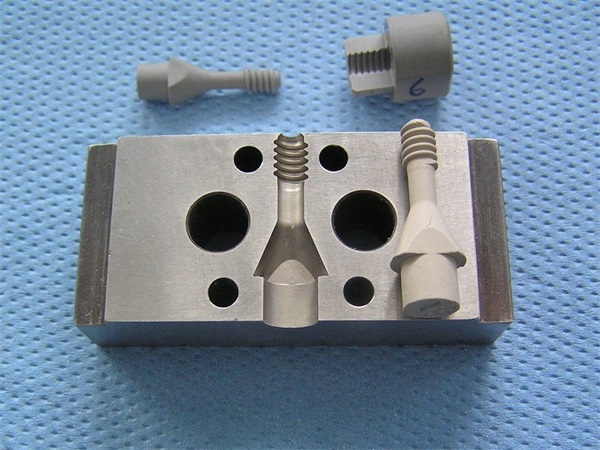

Also, it uses aluminum, silicone or temperature-resistant plastic as the primary material for the injection molds. Aluminum molds are easier and faster to create than steel molds, which can further help improve the speed of production.

What is High Pressure Injection Molding

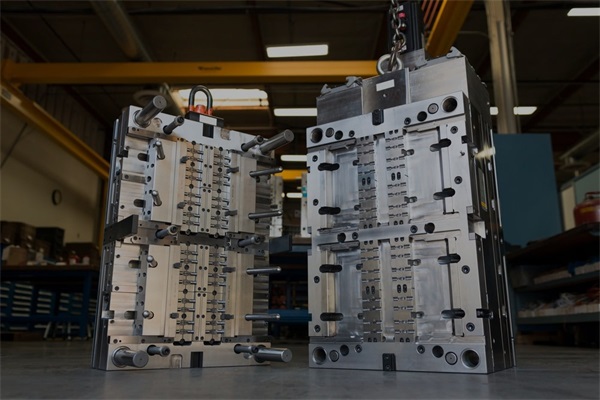

To achieve the best molding results, the injection molding machine can apply high pressure with slower speed, which will allow the plastic materials to follow the hollow mold cavities in a much better way. By applying the high pressure in the injection molding process, the details of the shapes or designs in the mold cavities can be transferred into the plastic materials with better accuracy.

However, this rapid manufacturing process will need to go at a slower pace, as the high-pressure application will need quite some time to get injection molds applied to the plastic materials. This is the type of injection molding process suitable for shaping prototypes, parts, and components with intricate geometries and complex designs in low to high volume, especially for the mass production.

Pros and Cons of Low Pressure Injection Molding

The low-pressure injection molding can handle simple molding processes and deliver the results for you fast. So, it is an excellent molding method for parts production in prototypes and low volume.

Pros

1. You can mold various parts and components with fast turnaround time and lower temperature when compared to the high-pressure method.

2. You can cut costs both on the plastic materials and the molds used in this process, as you can use the cheaper aluminum molds to get the injection molding process done.

3. It’s easier and faster to create the aluminum molds used in the low-pressure injection molding process.

4. You can reduce the rate of product defects during the production process, as the mold is easier to adjust and assembly

Cons

1. It is suitable only for quick prototypes or low-volume production.

2. You can’t produce hardware parts or components with high complexity in design.

3. You will need to replace the aluminum mold often during your production cycles.

Pros and Cons of High Pressure Injection Molding

The high-pressure injection molding offers a more thorough injection molding method, which can give various benefits for the manufacturers. For instance, with the high-pressure injection molding, the plastic materials can follow the shapes and designs of the mold cavities with more precision and accuracy. However, the process will be much slower when compared to the low-pressure injection molding method in low volume production.

Pros

1. This process is suitable for producing parts, and components with complex geometries and intricate design requirements.

2. You can use this injection molding method to produce various parts in a wide range of industries because of its flexibility and versatility.

3. It’s best for large production volumes or mass production by plastic multi-cavity moulds.

4. You can use various plastic materials, and it is easy to create distinctive color and finishing variations for the end products.

5. The waste materials are low and are also recyclable.

Cons

1. It is slower when compared to the low-pressure injection molding process in low volume manufacturing.

2. The initial tooling cost is more expensive than the simple low pressure injection mold.

3. There are some design limitations for the high-pressure injection molding process, even though you can produce more intricate designs compared to the low-pressure method.

Differences on The Low and High Pressure Injection Machines

In general, high speed, low pressure, or high-pressure low speed, "pressure" refers to the system set injection pressure, "speed" refers to the system set injection speed. When the temperature rises, it is beneficial to the flow of material and generally needs to reduce the pressure and speed. Conversely, when the temperature is lower, the pressure and speed should be increased. Pressure and speed need to match, usually called low voltage, high speed or high voltage, low speed is relative. Speed has a great effect on the amount of heat produced by shearing, so the speed is equivalent to warming up to some extent. Typically, the temperature is controlled first to see if the melt is in good condition. Then, according to the cavity structure, adjust the pressure and speed, multi-level adjustment, in order to mold filling and good appearance. Generally speaking, products of low speed and high-pressure ratio of the products of high-speed small shrinkage.

Hot melt material and injection method are different. Materials used in low-pressure injection molding are different from the ones used in traditional injection molding machines. Viscosity of the hot melt adhesive used for low pressure injection molding is low and it fluids quickly after being hot melted. And it does not extrude by the screw. It can be made to flow by the gear pump as long as it is heated and melted by the glue cylinder, with a small pressure. It goes into the mold, then cool the mold. So, the low-pressure injection molding machine does not have a screw device, and the glue is injected through the gear pump and the hose and the glue gun. This provides a good protection for fragile components.

Heating pressure, temperature is different. Low-pressure injection molding is injection molding by preheating the hot melt adhesive. Low-pressure injection molding materials have good adhesive ability and are unmatched by traditional engineering plastics. The temperature of the low-pressure injection molding process is much lower than the traditional high-pressure injection molding, which reduce the precision instruments damages caused by high temperatures.

Temperatures for low pressure injection molding is low, cast aluminum mold can be used. Compared to steel mold, aluminum mold is better for design and development. And the development cycle of the mold is shorter. Also, compared to traditional high-pressure injection mold, low-pressure hot melt adhesive injection molding process cycle is shorter.

Which is the Best One to Use

High pressure vs low pressure? For the overall quality and results for the product, it’s best to go with the high-pressure injection molding method. However, you can use the low-pressure injection molding method if you need to produce parts that have simple designs in rapid manufacturing process. Manufacturers will often choose between one or the other depending on the projects they need to complete.

Each production plan will have its own design requirements, and you can pick between the low-pressure and high-pressure injection molding process by looking at the design requirements you need to fulfill. Here are some important factors to look for before choosing between using low-pressure and high-pressure injection molding process:

Deadline

The production deadline matters for your choice of injection molding method. You can use the low-pressure injection molding method if the production deadline is too tight for you, as this method can deliver faster production cycles.

Parts Quality

The higher the quality of the parts you would like to get, the more it will be better for you to use the high-pressure injection molding process. The high-pressure injection molding method can provide you with the highest parts quality in your manufacturing process.

Plastic Materials

There are certain plastic materials that are suitable only for certain injection molding methods. For instance, epoxy resins and polyurethane resins are the materials best suited for you to use with the low-pressure injection molding method. So, you will need to use the low-pressure injection molding process if you only have these material options in your production.

Budget

Low-pressure injection molding is cheaper for you to use, as it uses cheaper aluminum molds, cheaper plastic materials, and quicker production cycles in low volume, especially in the insert molding and overmolding projects. For the projects that have a limited budget, the low-pressure injection molding technique is something that will provide the best results for you.

Conclusion of High Pressure vs Low Pressure Molding

The low-pressure injection molding method uses low pressure and high speed in its mold mechanism, whereas the high-pressure injection molding method uses high pressure and low speed in its mold mechanism. Thus, the two methods will offer different results.

Customers can pick the right plastic injection molding service method suitable for their project requirements. For instance, they can use the low-pressure injection molding method to produce parts with simple designs in a faster production cycle. Meanwhile, they can use the high-pressure injection molding method to produce the parts that have more intricate designs in medium to high volume.

Contact Us

Want to learn more about low-pressure injection molding vs. high-pressure injection molding? Or want to select the best process between them for your parts? TEAM RAPID is here to help.

Our experienced engineers and tooling specialists can:

- Evaluate your part design and functional requirements

- Recommend the best injection molding process for your application

- Optimize material, tooling, cycle time, and cost

- Support prototype development through mass production

TEAM Rapid has decades of experience in low to high volume injection molding and has series of injection molding machines that take orders for injection molding in all regions of the world. TEAM Rapid's professional team will provide you with integrated solutions from product design, manufacturing to sea delivery. Whether you’re looking for low-pressure molding for delicate assemblies or high-pressure molding for high-volume parts, our team can provide the guidance and manufacturing support you need.

Get in Touch

Email: [email protected]

Website:https://www.teamrapidtooling.com

Send your drawings or part specifications and our team will respond with expert feedback and a fast, competitive quote.

Contact TEAM RAPID to get started on your injection molding project!

Frequently Asked Questions (FAQs)

1. Which materials are suitable for low-pressure injection molding?

Soft or semi-rigid plastics and materials that are sensitive to high stress or heat, such asTPU, polyolefins, or overmolded elastomers are good forLow-pressure injection molding

2. When should I choose high-pressure injection molding?

When you meet the conditions of large production runs, parts with tight tolerances, complex geometries, or hard plastics, High-pressure injection molding is ideal! It ensures high precision, surface finish quality, and consistent repeatability.

3. Can I use the same mold for both low-pressure and high-pressure molding?

Not usually.

Low-pressure molds are designed for minimal stress and may not withstand high pressures.High-pressure molds are built for durability and precision under high force. Choosing the correct mold type is critical to part quality and tool longevity.

4. Which process is more cost-effective?

It depends on the volume:

- Low-pressure injection molding typically has lower tooling costs, especially for prototypes or small batches, but may have higher cycle times for larger parts.

- High-pressure injection molding has higher initial tooling costs but lower per-part costs for high-volume production due to faster cycles and material efficiency.