CNC Machined Heatsink – Design and Manufacturing

CNC machined heatsinks give precision thermal management solutions. The reason is standard extrusion profiles cannot meet complex design requirements. So you can achieve tight tolerances and custom geometries with machined heatsinks. In this process, computer-controlled machining processes change raw aluminum and copper blocks into optimized cooling parts.

Thermal Management Fundamentals

What is Heatsink

A heatsink transfers thermal energy from electronic parts to surrounding air. It uses three fundamental mechanisms. In the beginning, you need to understand these principles to design effective cooling solutions.

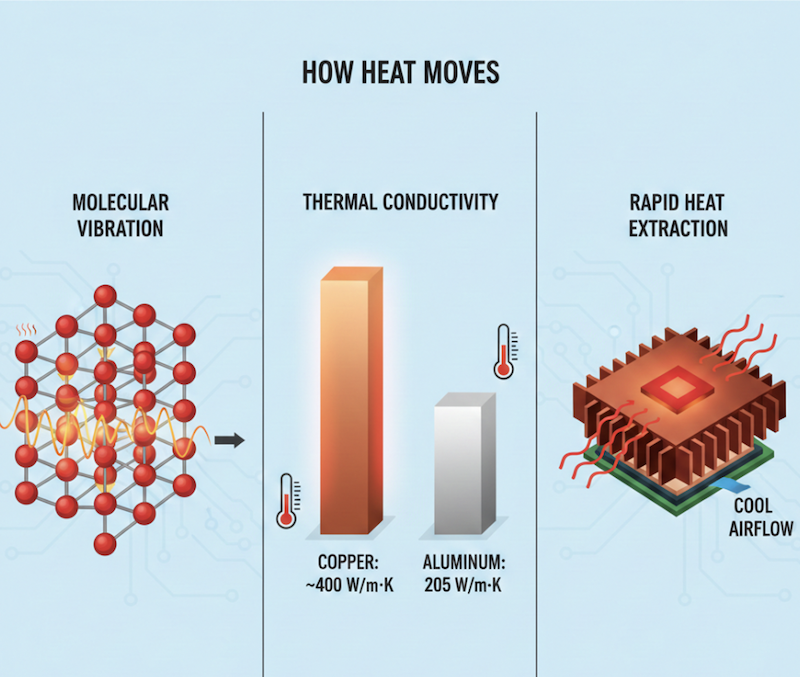

Conduction

First, heat moves through solid materials via molecular vibration. Then, copper transfers heat at approximately 400 W/m·K. Aluminum conducts at 205 W/m·K. You will notice copper heatsinks are good at rapid heat extraction. This is helpful for concentrated heat sources.

Convection

Air movement across fin surfaces carries heat away from the heatsink. Natural convection relies on thermal buoyancy. On the other hand, forced convection uses fans to increase airflow velocity. You should align fins parallel to airflow direction. This approach will maximize efficiency.

Radiation

Electromagnetic waves transport heat energy without requiring direct contact. Similarly, black anodized surfaces emit more thermal radiation than bare aluminum. This often just improves cooling in enclosed spaces. So convection becomes limited in these environments.

Thermal Resistance and Performance Metrics

Thermal resistance measures how effectively heat flows from junction to ambient. For example, lower values indicate better performance. You can calculate total resistance by adding part, interface, and heatsink resistances. Generally, a PC heatsink achieves 0.2-0.5°C/W. You should be able to verify these values through testing.

Heatsinks Applications and Cooling Challenges

Electronics generate more heat as power density increases. For instance, laptop heatsinks manage 45-65W processors in tight enclosures. GPU custom heatsinks must handle 250-350W loads. Industrial power electronics require rugged designs that maintain performance from -40°C to 125°C. Until then, standard designs would fail under such conditions.

Design Considerations for CNC Machined Heatsinks

Material Selection and Thermal Properties

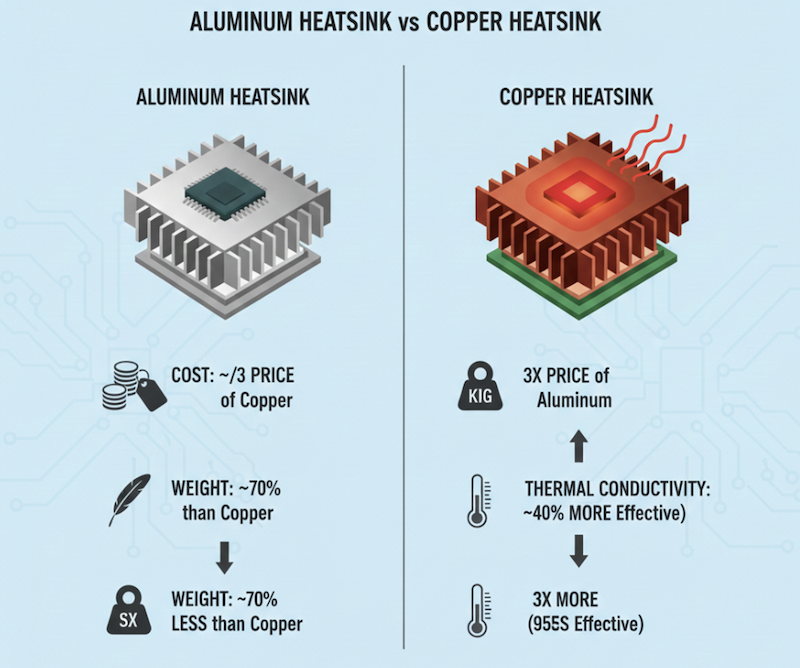

Aluminum Heatsink vs Copper Heatsink

The aluminum vs copper heatsink debate is about conductivity, weight, and cost. Aluminum costs one-third the price and weighs 70% less. However, copper vs aluminum heatsink comparisons show copper conducts heat 95% more effectively. There is no way to know which material suits your application without analyzing thermal requirements.

Aluminum Alloys 6061, 6063

Aluminum 6063 offers excellent machinability with thermal conductivity of 201 W/m·K. You can anodize this alloy to achieve various colors and improved corrosion resistance. Aluminum 6061 provides higher mechanical strength. It just means you get better structural properties for applications where the heatsink integrates with mounting brackets.

First, of course, you need to consider that aluminum heatsinks weigh significantly less. Second, evaluate the ease of manufacturing complex fin geometries. Third, account for aluminum's lower thermal conductivity when sizing fin arrays.

Copper

Copper heatsinks transfer heat 95% faster than aluminum but require specialized tooling. You will need sharper cutting tools and slower feed rates to prevent work hardening. Sure, the cost goes up, but performance improves dramatically.

On the other hand, copper's superior conductivity allows compact designs. The best way to do this is by reducing fin height while maintaining thermal performance. Such as the type found in telecommunications or aerospace electronics.

Hybrid Material Options

You can combine copper bases with aluminum fins to optimize heat absorption and dissipation. The copper base rapidly pulls heat from parts. Meanwhile, aluminum fins provide large surface area. Just make sure to minimize contact resistance between dissimilar metals.

Geometry and Fin Design

Fin Height, Thickness & Spacing Guidelines for CNC

You should design aluminum fins at least 1.0mm thick to prevent chatter. Keep height-to-thickness ratios below 10:1. Natural convection requires 3-5mm gaps. Forced air allows 1.5-2.5mm spacing. In terms of dense pin fin arrays, tighter spacing works with active cooling.

Pin vs Straight vs Complex Fin Configurations

Straight plate fins work best in directional airflow environments. Pin fins allow multidirectional cooling for uncertain airflow patterns. CNC machining enables offset fins, interrupted surfaces, and optimized geometries. You'd think all that complexity would be impossible through heatsink extrusion profiles.

Airflow Orientation

Natural convection heatsinks require vertical orientation with open top and bottom. You need wider fin spacing to avoid blocking buoyancy-driven airflow. Forced air designs permit horizontal mounting and tighter fin pitch. So you have more design flexibility with active cooling.

Mechanical and Integration Features

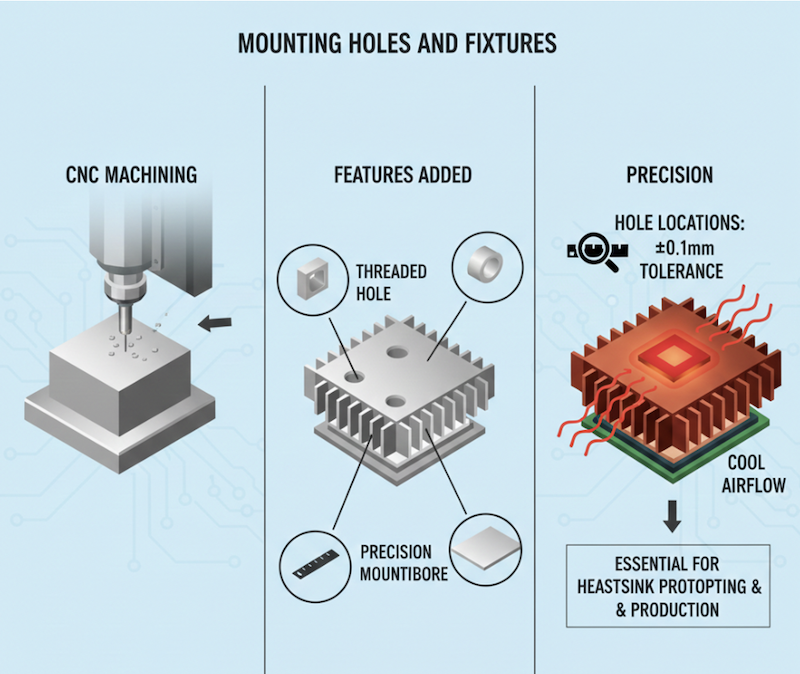

Mounting Holes and Fixtures

CNC machining adds threaded holes, counterbores, and precision mounting surfaces in a single setup. You should specify hole locations with ±0.1mm tolerance. Note that you always want this precision for heatsink prototyping and production.

Recesses and Pockets for Interfaces

You can machine recesses for thermal pads, TIMs, or part protrusions. Maintain a minimum base thickness of 2-3mm. You prefer this approach because the last thing you want to do is create weak points that fail under thermal stress.

Integration with Enclosure or parts

Multi-axis CNC operations enable heatsinks with integrated clips, standoffs, or alignment features. This reduces part count and assembly time. You would rather integrate features than add separate fasteners. Automotive and industrial applications benefit most.

Design for Manufacturability (DFM) in CNC Context

You should generally avoid deep pockets and narrow slots requiring long tool extensions. Use standard tool sizes to eliminate custom tooling costs. Add 2-3° draft angles to tall fins for easier machining.

Next, consolidate features to reduce tool changes. You can decrease machining time by grouping similar operations. So, aside from the cost savings, you get a faster turnaround.

CNC Machining for Heatsink Manufacturing

Overview of CNC Machining Processes

CNC Milling

Rotating cutting tools remove material to create fins, pockets, and mounting features. Three-axis mills handle most aluminum heatsink geometries. How often do you encounter designs needing five-axis capability? More frequently in aerospace than consumer electronics.

CNC Turning

Lathe operations produce cylindrical heatsink geometries and round pin fin arrays. You can then use live tooling to add cross-drilling and milling. In turn, this reduces production time and improves accuracy.

Multi-axis Machining for Complex Geometry

Four and five-axis CNC systems machine undercuts, angled fins, and curved surfaces in single setups. You will achieve better tolerance control by eliminating workpiece repositioning. This proves essential for heatsink prototype development. And you gain faster iteration cycles.

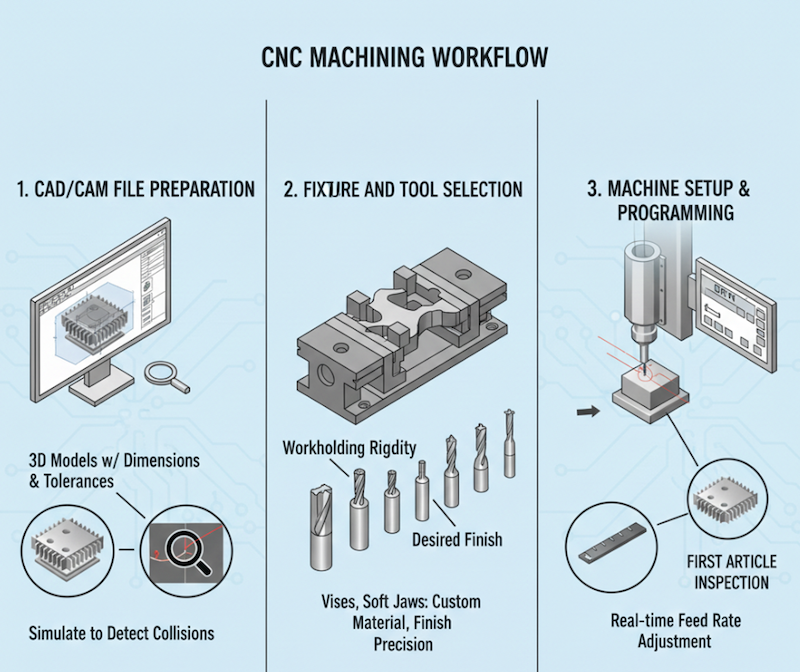

CNC Machining Workflow

CAD/CAM File Preparation

To begin, create 3D models with proper feature dimensioning and tolerance callouts. CAM software generates optimized toolpaths. You should simulate machining operations to detect collisions. Starting off with proper simulation prevents costly errors.

Fixture and Tool Selection

Workholding must balance accessibility with rigidity. You'll want to select vises, soft jaws, or custom fixtures based on part geometry. Tool selection considers material hardness, desired finish, and required precision. At the onset, proper fixture selection determines success.

Machine Setup and Programming

You should establish work coordinate systems using touch probes or edge finders. Program verification includes dry runs and first article inspection. Modern CNC controllers allow real-time feed rate adjustment. Originally, operators had to stop machines to make adjustments.

Part Machining and Quality Checks

In-process inspection catches dimensional errors before completing operations. You can use calipers, micrometers, and coordinate measuring machines. Surface finish measurements ensure thermal contact surfaces meet specifications. Consequently, you catch problems early.

Typical Capabilities and Equipment in Industry

3-Axis vs 4/5-Axis Machining for Fins & Complex Features

Standard vertical mills with three axes handle most requirements. Four-axis machining eliminates manual repositioning. Five-axis systems enable complex geometries with compound angles. Here's what the experts recommend: start with three-axis for prototypes, then upgrade for production.

Tolerance Ranges and Precision Levels

CNC machining achieves ±0.025mm for general features and ±0.01mm for critical dimensions. You will maintain these tolerances across production runs. Surface flatness reaches 0.005mm. Now, all of this stated, these capabilities exceed what extrusion gives.

CNC Machined Heatsink Manufacturing Process

Raw Material Preparation

The first step is to start with aluminum. Stock dimensions should provide adequate material while minimizing waste. You need to verify material certifications. Further, also observe surface defects before machining.

Rough Machining

The second step is roughing operations. In this operation, you remove bulk material quickly using larger diameter tools. You should leave 0.5-1.0mm stock for finishing passes. Finally, verify part dimensions after roughing to confirm adequate stock remains.

Feature Machining

After a few roughing passes, machine fins using smaller diameter end mills and higher spindle speeds. For example, thread milling produces accurate, burr-free threads for mounting hardware. Simultaneously, you can add lightening pockets and ventilation slots during this stage. Thirdly, inspect fin dimensions for accuracy.

Finishing Operations

Surface Finish

Final machining will improve surface quality and dimensional accuracy. You should use sharp tools, higher speeds, and lighter depths of cut. Thermal contact surfaces require fine finishes below 0.8μm Ra. Moreover, better finishes reduce contact resistance..

Surface Treatments

Black anodizing provides corrosion resistance and increased thermal emissivity. Subsequently, type II anodizing creates 10-25μm coating thickness. Type III hard anodizing reaches 50-100μm. You can specify custom colors for brand differentiation.

Nickel plating prevents oxidation on copper heatsinks. Furthermore, chromate conversion coatings give chemical resistance for harsh environments.

Deburring and Cleaning

After we finish carving the metal, the work isn't quite done because the part is often covered in sharp edges. You must clear these away, or the parts won't fit together properly and can even cut someone's hand during assembly.

Start shaking the parts in a vibrating machine to get them ready for the final check. We also use ultrasonic cleaning to clean oily cutting fluids.

Applications and Case Uses

Cooling Your Gadgets and LEDs

Power supplies have a lot of energy moving around in a very small space. We are talking about 100 to 500 watts of heat. To handle this, we use CNC machines to make special cooling fins and brackets all in one piece. For LED lights, the surface has to be perfectly flat so it can touch the cooling pad properly.

Keeping Networks and Motors Running

Network towers and industrial machines have a tough life because they sit outside in extreme heat or cold. When you design these, you have to add protective coatings and make sure they are bolted on very tightly. For heavy-duty motors, copper is the best choice because it moves heat faster than anything else.

Cars and Airplanes

CNC machining is best to make sealed designs and built-in mounts that won't break. In airplanes, every gram of weight matters, and we have to know exactly where the metal came from. Because CNC machining is so precise and reliable, aerospace companies have relied on it for years to make their most important cooling parts.

Testing Your Ideas

The best thing about CNC machining is how it helps us when we are just starting a project. If you want to try three different designs to see which one cools better, you can do it fast. You don't have to spend a lot of money on expensive molds or tools every time you change a small detail. Once you find the perfect design through these tests, you can then decide if you want to stick with machining or move to a different method for making thousands of them.

Challenges and Best Practices

Machining Copper Fins

Copper work hardens rapidly during cutting operations. You should use positive rake angle tools and maintain sharp edges. Reduced cutting speeds extend tool life but increase cycle time. Consider using carbide tools with specialized coatings for improved wear resistance.

Then, you will need frequent tool changes to maintain dimensional accuracy. You can monitor cutting forces and vibration to predict tool failure.

Balancing Thermal Performance with Manufacturability

Optimal thermal designs often conflict with manufacturing constraints. You need to work iteratively between thermal simulation and DFM analysis. Adding small radii to fin roots improves machinability. This change does not significantly degrade heat transfer. You should prioritize features that give measurable performance gains.

Cost Optimization Strategies

You can reduce machining time by using larger tools for non-critical features. Consolidate setups to minimize handling operations. Standard mounting patterns eliminate custom tooling requirements. Furthermore, you will improve yield by optimizing blank sizes and nesting multiple parts.

Iterative Design, Simulation, and Prototyping

Use computational fluid dynamics to predict thermal performance before cutting metal. You should prototype with simplified geometries first, then add complexity based on test results. Measure actual thermal resistance and compare against predictions. This avoids costly mistakes in heatsink manufacturing.

Conclusion

CNC machined heatsinks provide unmatched design flexibility. They give precision for demanding thermal management applications. You gain the ability to create custom geometries. You can integrate mechanical features. You can also optimize performance through iterative prototyping. Standard extrusion cannot match these capabilities for complex thermal challenges.

Contact Us

Have questions or ready to get a quote for your custom CNC machined heatsink? Our expert team at Team Rapid Manufacturing Co., Ltd is here to help! We offer precision CNC machining and rapid manufacturing solutions tailored to your design and performance needs. Whether you need thermal management parts, tight tolerance features, or custom geometries, we’ll work with you from design to delivery.

Email: [email protected]

Phone:+86 760 8850 8730

Website: www.teamrapidtooling.com

Why Contact Us

- Fast, accurate quotes and professional DFM feedback

- Experienced engineers ready to support your project

- Global service and shipping to the USA, Europe, and beyond

How to Get Started

- Send us yourCAD files (STEP/IGES/STL)with quantity, material & finish requirements.

- Tell us your expected delivery timeline and application.

- We’ll reply with a quote and engineering suggestions — typically within 24 hours.

Let’s bring your next heatsink design to life — contact us today!