Instruction of Some Injection Molding Gate Types

When you start with an injection molding project, you need to think about the gate location and appropriate gate type. Here, we are going to talk about some universal Injection Molding Gate Types.

Some Injection Molding Gate Types

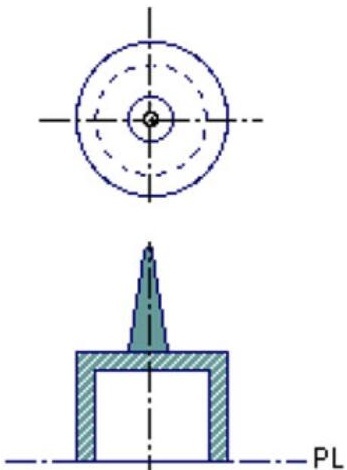

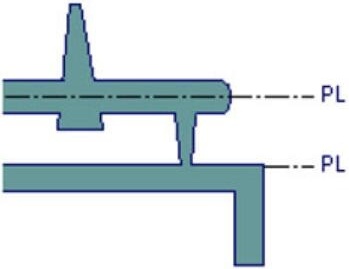

Direct Gate

It is commonly used in single cavity mold. Benefit from this gate type, you can feed your part in shorter time and less injection pressure, but the disadvantage is difficult to remove gate residue after injection, also, the gate marks left will be obvious. So, direct gate always been set in some unseen and non-cosmetic surface. Some house appliance and consumer products such as printer, washing machine, TV etc are used this gate type.

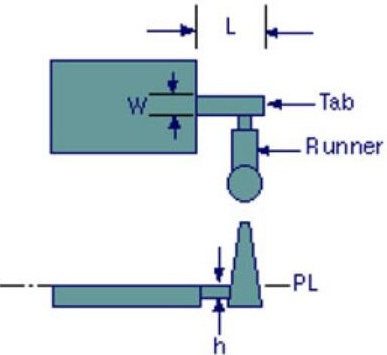

Tab Gate

For the long flat injection molded parts, we usually use tab gate for feeding. It is normally in size of 3/4 of the wall thickness and set at the narrow side. It works at reducing the shear stress generated around the gate location. But you need to take care about the flow marks, especially for PC parts in transparent (You can raise the mold temperature to reduce flow marks).

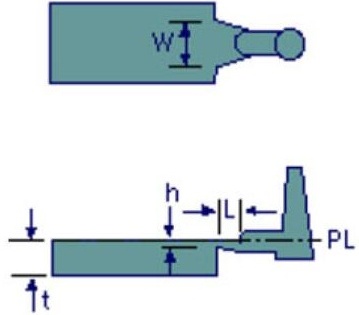

Fan Gate

Just like the name suggest, fan gate allows melt plastic flow into the cavity through a wide opening like a fan. It can create a quite stable flow, which is helpful to reduce deformation and maintain dimensional stability.

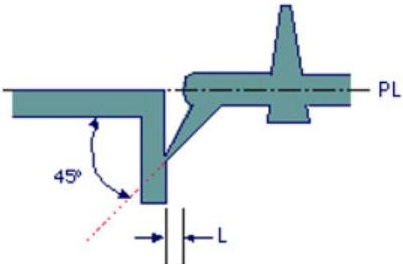

Sub Gate

Sub gate is always setting on the uncritical surface, as the Injection Moulding point is small, and the gate mark is not obvious after ejection. The gate residue will be trimmed off along with the action of injection mold open, so the sub gate is widely applied in automatically plastic products production.

Pin Gate

Compared with the mentioned 4 gate types, the structure of pin gate is a bit complex. It is specially used for 3 plates mold. The runner channel are located in a separate plate, the melt plastic run through these channel and enter into the cavity via one or several small gate (the gate size is small, it looks like a small pin), the gate is allow to be trimmed off along the action of mold opening. As the longer runner, the scrapes rate by pin gate would be higher.

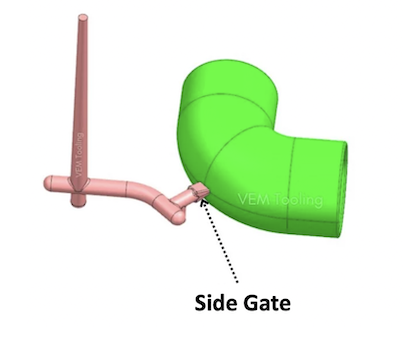

Side Gate

Side gate, we also call it edge gate, it is one of the most versatile and widely used gate type in plastic injection molding. The gate is designed on the parting line, the melt enter from the side of the cavity. This gate type layout is reliable option for both single-cavity mold and multi-cavity moulds. Also, it is simple to trim manually or automatically, and the runner system can be flexible.

Injection Molding Gate Types Comparison

|

Gate Type |

How It Works | Advantages | Disadvantages | Applications | Materials Used | Gate Size Range |

|---|---|---|---|---|---|---|

| Side Gate (Edge Gate) | A rectangular opening on the parting line that introduces melt from the part’s edge. | 1.Low tooling cost 2.Predictable flow 3.Easy to tune during sampling | 1.Visible edge vestige 2.Requires trimming 3.Not ideal for premium surfaces | 1.General housings 2.Multi-cavity molds 3.Medium-thick wall parts | ABS, PP, PE, PS, PA | Width: 1.0–3.0 mmThickness: 0.8–1.5 mmWider for PP/PE, smaller for ABS/PS. |

| Tab Gate | A small “tab” between the runner and part helps slow and distribute material before filling. | 1.Reduces shear & jetting 2.Good for cosmetic surfaces 3.Simple modification | 1.Large trimming area 2.Takes up space 3.Not ideal for tight edge tolerances | 1.Flat plates 2.Thin cosmetic parts 3.Stress-sensitive materials | ABS, PMMA, PC+ABS, HIPS | Tab Width: 3–8 mmTab Thickness: 1.0–1.8 mm Designed larger to absorb shear. |

| Fan Gate | Melt spreads through a wide, thin “fan” opening for even distribution. | 1.Excellent for wide/thin parts 2.Smooth filling & low warpage 3.Good dimensional stability | 1.Larger trim area 2.More mold work 3.Not suited for compact parts | 1.Thin covers & lids 2.Large surface parts 3.Components requiring uniform flow | PP, PS, ABS, PC, TPE | Fan Width: 8–25 mmThickness: 0.6–1.2 mm Thin for stiff plastics, thicker for TPE. |

| Submarine Gate (Tunnel / Sub Gate) | A hidden tunnel introduces melt then automatically breaks off during ejection. | 1.Very small vestige 2.Automatic degating 3.Great for cosmetics | 1.Harder to machine 2.Not ideal for very large flow rates 3.Higher tooling cost | 1.Electronics housings 2.Visible consumer parts 3.High-volume molds | ABS, PC, POM, PP, PA | Diameter: 0.8–1.2 mm (common)Max: 1.5 mm for higher-flow materials.Clean break needed for cosmetics. |

| Pin Gate (Point Gate) | Small circular gate used with 3-plate or hot-runner systems for balanced filling. | 1.Minimal gate scar 2.Great for small parts 3.Works well in multi-cavity molds | 1.More complex mold 2.Not for very viscous materials 3.Can freeze off quickly if undersized | 1.Precision parts 2.Cosmetic components 3.Electronics and medical items | PC, ABS, PMMA, PBT, Nylon | Diameter: 0.6–1.5 mm Hot runner: 0.8–1.2 mm Cold runner: 1.0–1.5 mm |

| Direct / Sprue Gate | Melt flows straight from sprue to cavity, commonly used for single-cavity molds. | 1.Strong packing pressure 2.Simple mold design 3.Good for thick parts | 1.Very large vestige 2.Longer cooling 3.Requires manual trim | 1.Large/thick parts 2.Low-volume jobs 3.Non-cosmetic components | PC, PA, POM, PP, PE | Sprue Diameter: 2.0–6.0 mmLarger gates used when packing thick sections. |

More Suggestions on Gate Types Selection

Aesthetic / Cosmetic priorityis Critical?

- Submarine Gate or Pin Gate is the first choice— they minimize visible gate scars.These are preferred for the critical surfaces.

Large, flat or thin-walled parts which require uniform fill and low stress / warpage?

- Fan Gate is the best choice: its wide fan-shaped entry helps distribute melt evenly and reduces internal stresses.

Simple, economical molds with moderate aesthetic requirement or hidden edges?

- Side Gate(orTab Gate) is a good balance of cost, simplicity, and manufacturability — especially for housings, enclosures, general-purpose parts.

High-volume production with automation and minimal manual labor?

- Submarine Gate(automatic degating) or Pin Gate(with hot-runner systems) tend to be most efficient.On can consider the banner gate as well.

Thick-walled or bulky parts with low aesthetic demand?

- Direct / Sprue Gate might still be the easiest/most effective choice.The gate residue be removed by trimming or machining, as the gate size is big.

When part geometry is flat but needs controlled flow entry (avoid jetting, stress at entry)?

- Tab Gate— because the tab acts as buffer absorbing shear/stress before main cavity flow.

Injection Molding Services China - TEAM Rapid

The gate type is directly effects on the molding quality, cycle time, and production efficiency, so how to choose the right gating type is important! TEAM RAPID specializes in rapid tooling, plastic injection molding, and on-demand manufacturing for customers across different industries, our team is here to provide the best engineering support, material suggestions, or help optimizing your mold design. TEAM RAPID is a professional rapid manufacturing company. We offer Injection Molding Service to meet your different volume production needs. No matter 50 or 100,000 parts, we can provide the best solution to you.

Get In Touch

To discuss your project, request a consultation, or inquire about our services, please use the contact information below:

|

Contact Method |

Details |

|

|

|

|

Telephone |

+86 760 8850 8730 |

You can also send us your 3D files (STEP, IGES, X_T) and project requirements. We typically respond within 12 hours with a detailed quote and manufacturability recommendations.

Injection Molding Gate Type FAQs

1. How do I choose the right gate type for my injection-molded part?

Choosing the right gate depends on your part’s shape, cosmetic requirements, and production goals.

Here are the key factors:

· Part appearance:Use submarine or pin gates if you want minimal gate marks.

· Part size:Larger or wide parts often benefit from fan gates for uniform filling.

· Material flow:High-viscosity materials may require larger edge or tab gates.

· Automation needs:Submarine gates allow automatic degating.

· Wall thickness:Thin-wall parts usually need wider, thinner gate designs.

Most projects start with common, cost-effective gates like side or tab gates and upgrade only if the part requires better cosmetics or more controlled flow.

2. What defects can be caused by choosing the wrong gate type or gate location?

Poor gate design can directly cause molding defects, including:

· Jetting:Caused by high-velocity melt entering through a small gate (tab or fan gate can fix this).

· Flow marks / ripples:Often due to improper gate position or too small of a gate.

· Burn marks:Caused by trapped air when the flow front enters from the wrong direction.

· Sink marks:Result from thick gate areas or poor cooling around the gate.

· Warping:Occurs when the flow is unbalanced or the gate is feeding asymmetrically.

· Short shots:Gate freezes too early or is undersized.

Choosing the correct gate type and location is one of the most effective ways to prevent these issues.