Why Should I Consider Low Volume Manufacturing

Comparing with the mass production, low volume manufacturing should be more beneficial for the developing company and product development. Here, we are going to talk about the reason why we consider about low volume manufacturing.

Development of Low-Volume Manufacturing for Custom Products

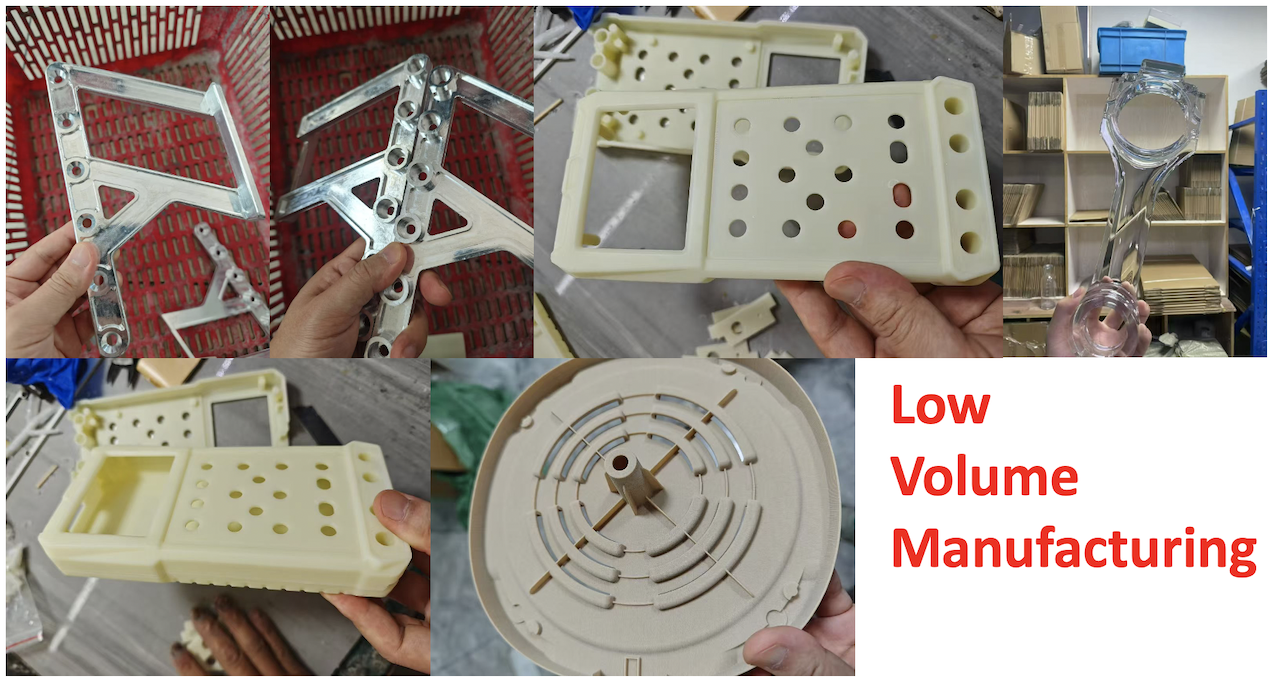

For modern product development, low-volume manufacturing for custom products has evolved from a niche production method into a core strategy.As markets demand faster innovation, greater customization, and lower risk, manufacturers and product owners are increasingly relying on low-volume production to bridge the gap between concept, prototype, and full-scale manufacturing. This development is closely tied to advances in digital manufacturing, CNC machining, rapid manufacturing and flexible supply chains.

Benefits of Low Volume Manufacturing

1. Low volume manufacturing can save your money.

You can buy small volume parts by less investment, and drop the money into market developing. This can also contribute to saving costs by no inventories and have a fast turnover.

2. Low volume manufacturing allows faster time to market.

Timing is critical for products launching. Every minute can lead to different result in marketing, especially for the new product introduction.Low Volume Manufacturing allows you to get the new products in short time, you can have a quickly promotion to win the orders.

3. Low volume manufacturing can give flexibility to companies.

Low volume manufacturing allows you more time to test the market. After testing, you can know whether your products will be popular in the market, then develop a series of new types to meet the public’s favors.

4. Low volume manufacturing can be option for bridge production.

When your product is demanding quickly, you can switch the manufacturing method from Low Volume Manufacturing to mass production, which is safer and easier.

Tips for Choosing a China Low-Volume Supplier China

- Process breadth: For custom products, it’s often better to work with manufacturers that handle multiple processes (CNC, EDM, grinding, finishes) so your parts can be completed under one project team.

- Communication & support: Responsive engineering and project management (English-friendly) improve quality and delivery on custom requirements.

- Quality systems: ISO certifications (e.g., ISO 9001, ISO 13485 for medical parts) help ensure inspection consistency.

- Export experience: Suppliers who regularly ship to EU/US are familiar with packaging, documentation, and compliance expectations.

Featured Supplier for Custom Low-Volume Manufacturing

TEAM RAPID Manufacturing Co., Ltd

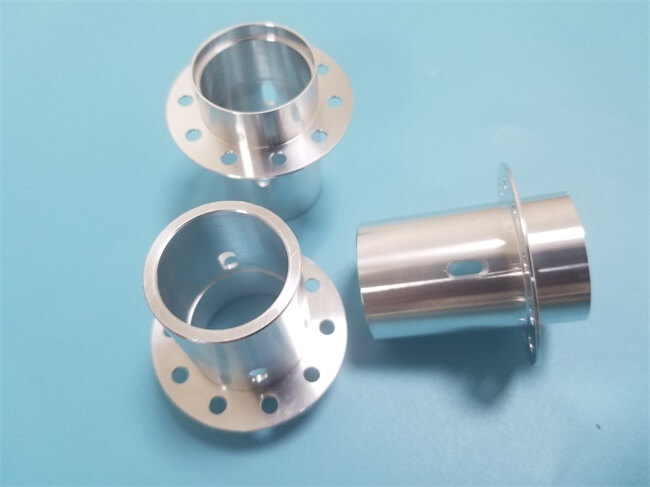

TEAM RAPID is a one-stop rapid manufacturing supplier based inZhongshan, Guangdong Province, China.We specialize in rapid prototyping and volume manufacturing with services that include CNC machining (milling, turning, EDM, and other processes), injection molding, die casting, sheet metal fabrication, and rapid tooling — all tailored for custom product runs.

Why choose TEAM RAPID:

- Comprehensive services:from rapid prototype to low-volume manufacturing under one roof.

- Flexible volumes:from single prototypes up to 100,000+ parts depending on process and product.

- Global experience:serves customers in the USA, UK, Germany, and more with engineering support.

- Quality assurance:competitive pricing and high quality parts.

TEAM RAPID offer full rapid manufacturing services include rapid prototyping, CNC machining and rapid injection molding to meet your low to high volume manufacturing needs. We aim to provide high quality parts at lower cost and shorter lead-time. Contact us at [email protected] to learn more.