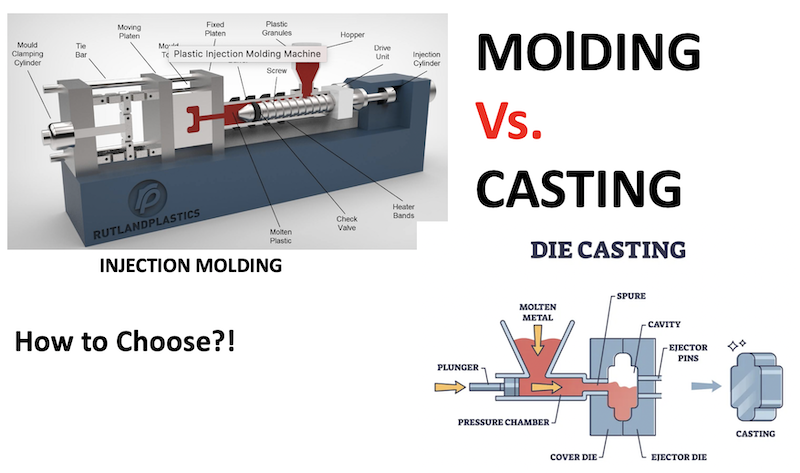

What Is the Different between Molding and Casting

Molding and casting are 2 different manufacturing processes. They have differences, but both of them are closely related, we can say they are some how and the same thing, here we are going to talk about the different between Molding And Casting.

The Molding and Casting Differences

Materials Different

They are related pouring molten liquid into a mold/die which will solidify the shape of cavity mold and die after cooling down. The differences is at pouring material, plastic is for molding, metal is for casting.

Machines and Parameters Different

The equipment or the method by pouring molten liquid is different for molding and casting. The injection pressure and clamping force for high die casting is much more than injection molding. Also, the working temperature for pressure die casting is far more than Injection Molding.

Post Finish and Costs Different

Molding can give you a final product but in case of casting, you may need to do post machining or post finishing to remove some features or deburred. Typically, the cost for molding is less expensive than casting, not only for the product but also for the tooling.

Differences Between Molding and Casting - The More Details

Aspect

Molding

Casting

Definition

Shapes material by injecting or pressing it into a mold under pressure

Forms parts by pouring liquid material into a mold and allowing it to solidify

Material State

Softened or molten material

Fully liquid material

Common Materials

Plastics, rubber, silicone

Metals (aluminum, steel, zinc), resins

Pressure Used

Medium to high pressure

Low pressure or gravity (some processes use pressure)

Mold Type

Typically rigid, precision steel or aluminum molds

Sand, metal, ceramic, or silicone molds

Tooling Cost

Higher initial mold cost

Lower initial mold cost (varies by process)

Production Volume

Best for medium to high volumes

Suitable for low to medium volumes

Dimensional Accuracy

Very high, tight tolerances

Good, often requires post-machining

Surface Finish

Excellent, near-net shape

Good to excellent, process-dependent

Post-Processing

Minimal

Often required (machining, polishing)

Typical Applications

Plastic housings, consumer products, connectors

Engine parts, structural components, metal housings

Molding or Casting - How to Choose the Process for My Product

Nowadays, the product usually made combine plastic and metal, it is essential for a high-quality final build to choose the right molding and casting – or using them together to make product. At TEAM RAPID, we provide integrated solutions for both, ensuring your plastic and metal components fit and function perfectly together.

Choosing the Right Process for Your Material

While the terms are sometimes used interchangeably, the industry generally separates them by material type:

Plastic Parts: Injection Molding

For plastic components,Injection Molding is the standard. It involves injecting molten resin into a steel or aluminum mold at high pressure.

- Best for:Enclosures, buttons, internal brackets, and high-volume consumer goods.

- Key Advantage:Exceptional speed and the ability to produce millions of identical parts with tight tolerances.

Metal Parts: Die Casting

For metal components,Die Casting is the most efficient counterpart to injection molding. It forces molten metal (like aluminum or zinc) into a steel die.

- Best for:Structural frames, heat sinks, engine components, and heavy-duty housings.

- Key Advantage:High strength, excellent thermal conductivity, and a premium "metallic" feel.

Contact TEAM RAPID for Molding and Casting

TEAM RAPID provides both rapid injection molding and Pressure Die Casting Service. We specialize not only for the mass production but also for low volume manufacturing. Want to know more about our capability and see if we can help for your next project? Contact our team at [email protected] today to request a rapid manufacturing quote.